GFRC Fixing Methods for Optimal Performance

Proper fixing methods are crucial for the long-term performance and aesthetic integrity of GFRC cladding. They must secure panels, accommodate movement, allow for construction inaccuracies, and maintain integrity under various conditions like impact, vibration, wind, and fire. It's essential to avoid "over-fixing" GRC panels, as this can inhibit natural movements and lead to detrimental cracking.

Common Fixing Methods:

Face Fix / Direct fix: Used where access is restricted or panels are small, with the fixings visible on the panel's face. Face fixings at the base of the panel provide vertical support through their shear resistance, while all fixings provide lateral support.

Bracket Fix: This method typically involves stainless steel cast-in sockets anchored into the GRC panel, spreading the load over a larger area. These sockets should be encapsulated in an adequate volume of GRC with good fibre distribution and left slightly proud of the GRC surface to prevent damage from overtightening.

GFRC Panels with Steel Sub-frame Support: This advanced method involves attaching the GFRC skin to a prefabricated metal frame. This is commonly used for large panels and is the preferred method for constructing back-ventilated and drained rainscreens.

Key Components of Sub-frame Support:

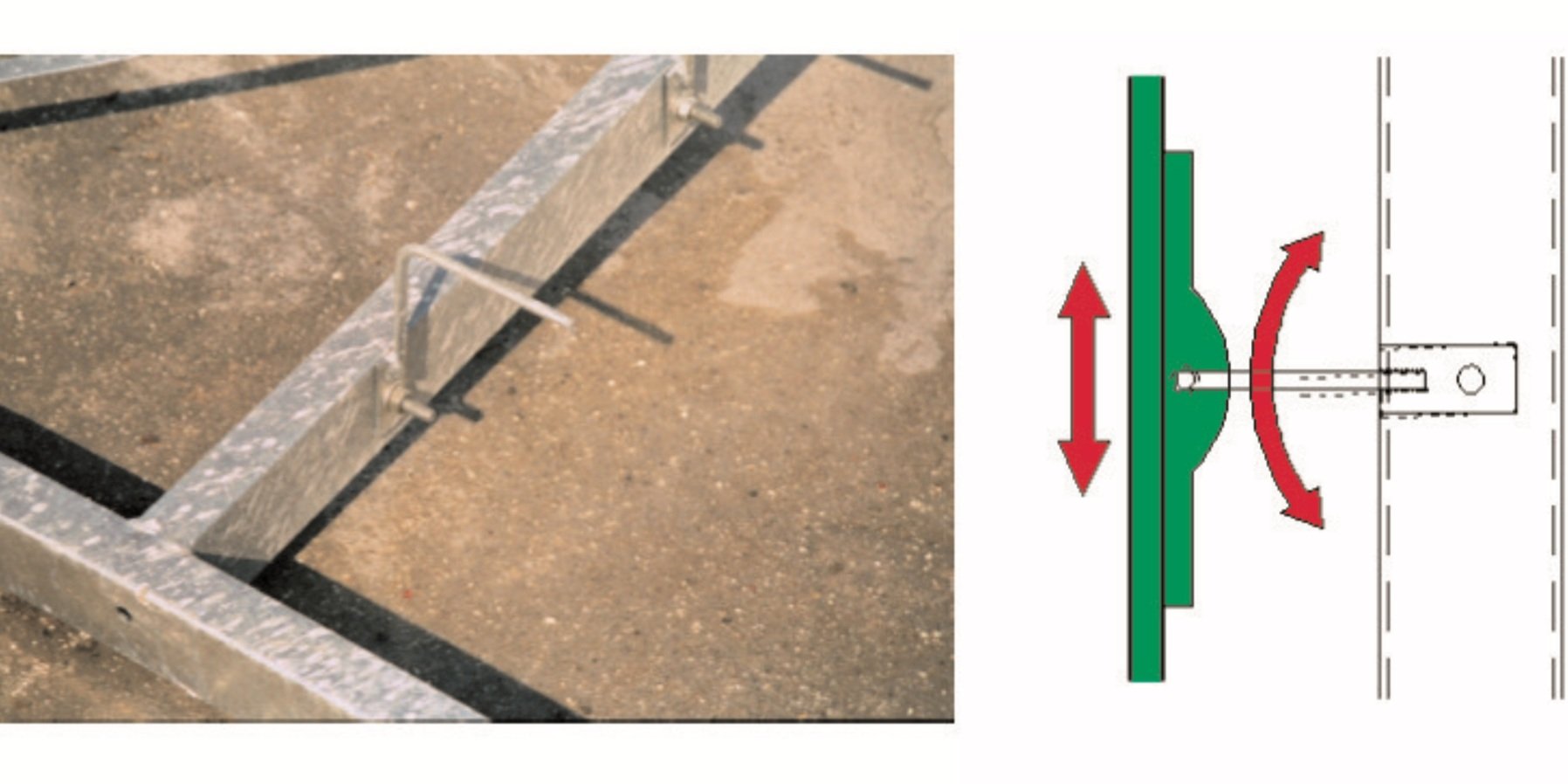

Flex Anchors: L-shaped flexible anchors provide lateral support to the GRC facing while allowing for rotation and shrinkage/moisture movement.

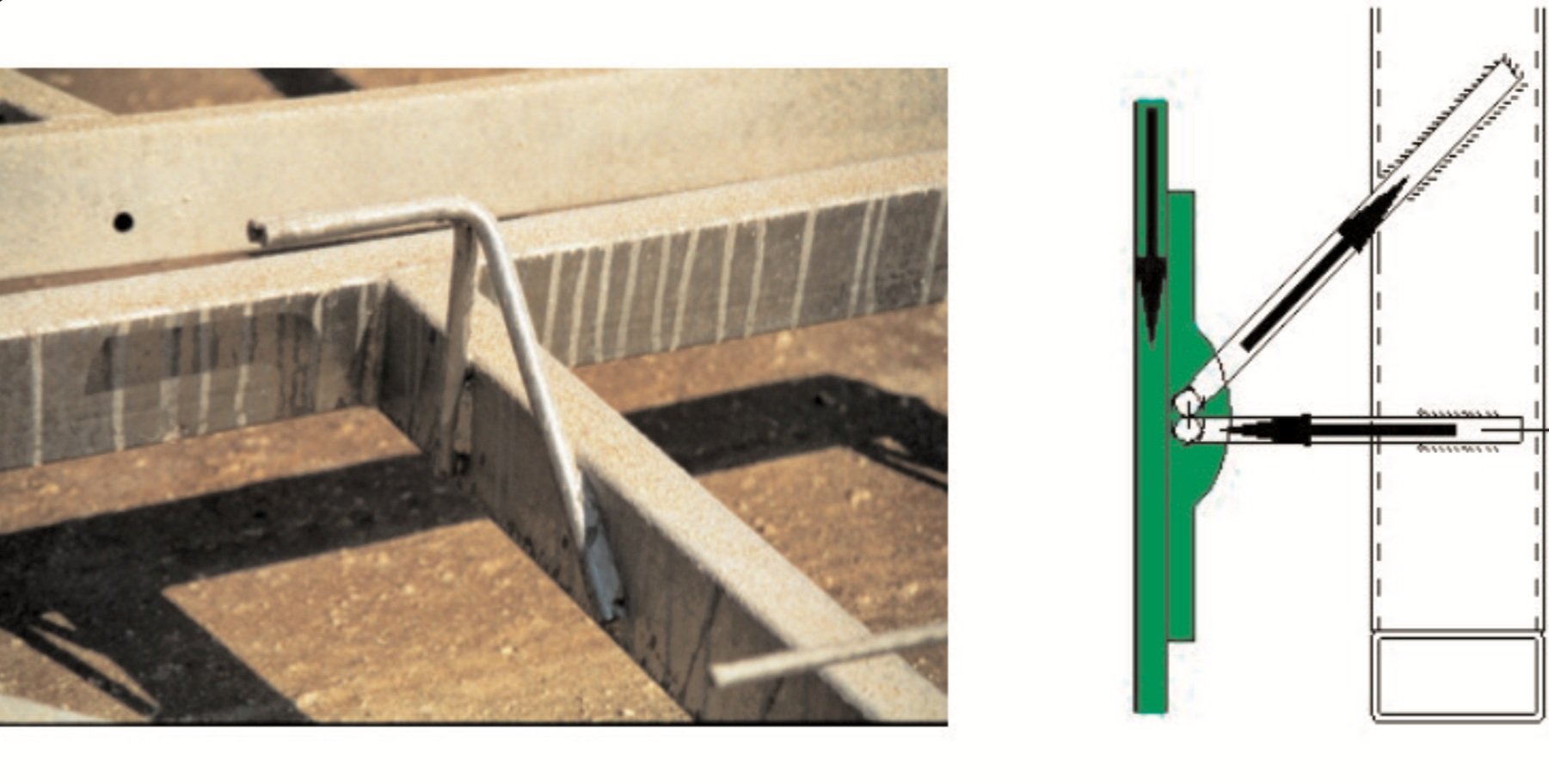

Gravity Anchors: Positioned along the bottom of the panels, these anchors support the self-weight of the GRC. They also stabilize the construction against wind action in service conditions. All gravity and flex anchors should point towards the center of the panel to alleviate adverse shrinkage stresses and should be fitted with debonding sleeves.

Threaded Inserts: Inserts are threaded connectors cast into GRC panels or structures during manufacturing. They help attach other parts to the GRC panels.

Mechanical Anchors for Veneers: For unbonded veneer facings like brick or natural stone fixed to the GRC surface, mechanical anchors connect them while allowing movement between veneer and GRC caused by temperature and moisture changes. These stainless steel anchors are set into the GRC and made to permit this movement. A bond breaker is usually placed between the veneer and GRC backing when using these anchors.

Typical stud frame

Example flex anchor

Example gravity anchor

Important Design Considerations for Fixings:

Movement Accommodation: Fixings must allow for translational and rotational movements between panels and the supporting structure, while maintaining waterproofing at joints. GRC is susceptible to dimensional changes due to wetting and drying, as well as thermal movements. These movements must not be inhibited.

Tolerances: Adequate tolerances must be incorporated into the fixing system to accommodate normal construction inaccuracies and anticipated movements.

Material Selection & Durability: Stainless steel fixings are generally recommended due to their high corrosion resistance and long life, especially in inaccessible locations or corrosive environments. Galvanised fixings have a finite life proportional to the zinc coating thickness.

Galvanic Corrosion Prevention: When dissimilar metals are in contact, galvanic corrosion can occur. This can be prevented by excluding water or isolating the metals with non-conductive materials like plastic or rubber gaskets and nylon/Teflon washers.

Lifting and Handling Fixings: Separate fixings should always be provided for lifting and handling purposes to avoid damaging permanent fixings. Lifting points should be symmetrically placed about the panel's center of gravity.

Early Design Coordination is Key

To ensure a safe, efficient, and economic fixing system, early design coordination between the Architect, Structural Engineer, and GRC Cladding Designer is paramount. Involving glazing/curtain walling specialists in these discussions is also advisable to address interface issues